Green Shipbuilding with Damen Shipyards

Platform Zero is dedicated to promoting green practices in the maritime and energy sector. Through informative articles based on research and expert interviews, we aim to educate readers on sector trends. If you’re an expert interested in contributing, contact us at info@platformzero.co!

In response to escalating global environmental concerns and regulatory pressures, the maritime industry is undergoing a profound transformation towards green shipbuilding. This article delves into the industry’s sustainability challenges and the cutting-edge solutions that address everything from material sustainability to fuel choices. It explores Damen Shipyards‘ role in navigating these complexities, emphasizing a comprehensive approach that extends beyond fuel alternatives to encompass recycling, waste reduction, and collaborative initiatives at the grassroots level. Read the article below to gain some insights on green shipbuilding.

Insights on sustainable shipbuilding practices from Damen Shipyards

Rotterdam, January 15 , 2024

With a growing global interest in environmental preservation, the maritime industry has embarked on a journey toward implementing innovative solutions for green shipbuilding. Development towards more sustainable shipbuilding practices not only aligns with market trends but also responds to regulatory pressures, incentivizing the maritime transport sector to enhance its environmental performance. Shipbuilders and naval architects are at the forefront, leading the movement towards green shipbuilding through innovative solutions. In this article, we explore industry challenges and the solutions contributing to the reduction of carbon emissions in the maritime industry, with insights from Damen Shipyards, an international shipyard group committed to becoming the most sustainable maritime solution provider in the world.

To have a more indepth look in the industry, we have interviewed Pieter Huyskens, Director of the Research, Development and Innovation department at Damen Shipyard. Damen offers maritime solutions through design, shipbuilding, and ship repair. As part of their sustainability strategy, Damen aims to:

“Reducing our waste, reducing our energy needs, and trying to use as much renewables for our energy as we can”

Navigating Sustainability Across Ships Lifecycle

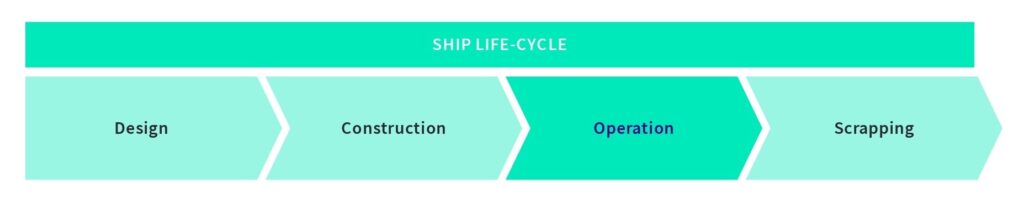

Traditionally, shipbuilding practices in the maritime sector have often relied on materials and methods that may be considered unsustainable by today’s environmental standards. This impact, from an energy-intensive industry, originates from different parts of the lifecycle of ships. From ship design and production to its operational phase, the industry has traditionally relied on materials and methods that contribute significantly to environmental degradation. Notably, unsuccessful ship-breaking, scrapping, or recycling processes further exacerbate the problem, resulting in substantial material waste and environmental impact.

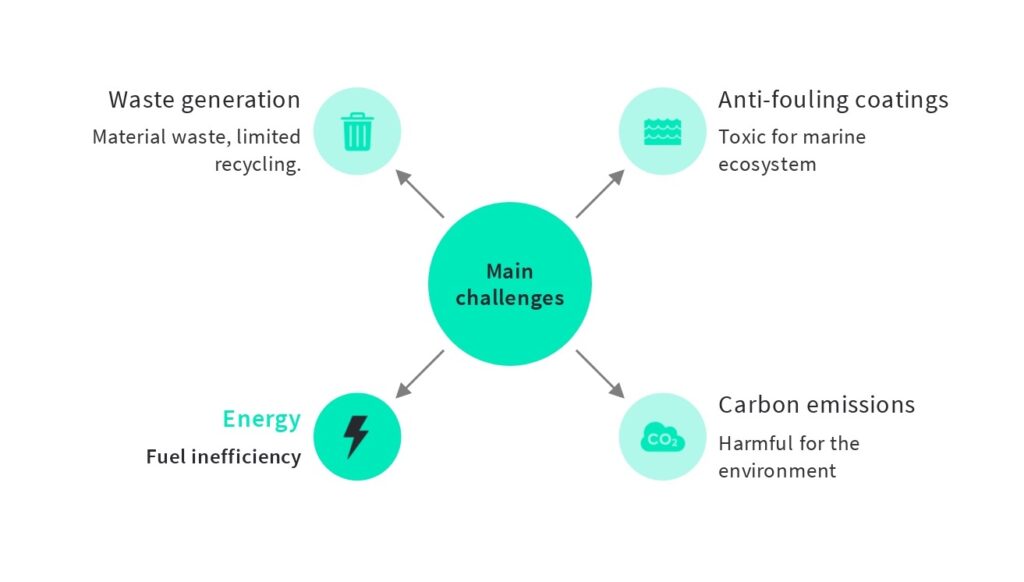

The maritime sector has a responsibility to tackle climate change and shipbuilders are rising to the challenge by introducing sustainable practices in order to reduce the carbon footprint of vessels throughout their life cycle. Several of the main sustainability challenges in the sector are the following: material sourcing, anti-fouling coatings, fuel inefficiency, emission reduction, waste generation, and limited recycling. Traditional shipbuilding often involved significant use of materials, such as steel requiring energy-intensive manufacturing processes and coatings toxic for marine ecosystems.

Innovative Approaches to Sustainable Ship Design and Technology

To tackle these challenges, the adoption of alternative materials, such as eco-friendly composites, lightweight alloys, and non toxic coatings, reduces harmful impact on the environment. While green steel is starting to gain traction in the industry, they are mostly produced in Europe. As Damen builds vessels all around the world, they have to assess the transportation impact of green steel to all their production locations.

“Sustainable steel is not made all over the world and if you have to transport sustainable steel made in Europe to the yards in Asia, the steel might not be all that sustainable anymore”

To address the limitations of conventional ship design, Damen’s modular design serves as a strategy to manage the escalating complexity and rapid innovation in response to sustainability and advancements in propulsion technology. Although optimizing design and production processes can contribute to a reduction in the industry’s overall footprint, the greatest potential lies in focusing on the entire lifecycle of ships, where substantial energy consumption occurs.

To this end, green technologies are increasingly gaining traction in the maritime industry, encompassing cleaner propulsion systems, energy-efficient designs, the use of alternative fuels, and the integration of renewable energy. For Damen Shipyards, the most promising opportunity lies in e-fuels, with methanol standing out as a potential solution to re-use carbon emissions, garnering significant attention within the industry.

“Many ship operators are now seeing that methanol is probably here to stay”, Pieter notes.

Methanol presents a compelling sustainable alternative due to its potential to significantly repurpose carbon emissions in the maritime sector. The liquid nature of methanol at ambient conditions facilitates practical storage and handling, enhancing its viability as a feasible and cleaner fuel option. Despite its potential, Damen points out challenges such as engine availability and uncertainties regarding the carbon source for these fuels, reflecting the complexities associated with the industry’s transition towards greener solutions.

Going the Extra Mile: Sustaining the Maritime Lifecycle

Furthermore, sustainable initiatives extend beyond fuel choices, encompassing smaller-scale movements that focus on recycling ship parts, local waste reduction initiatives, and the implementation of circular economy practices to prolong the life cycle of ship materials. In line with these efforts, Damen Shipyards has for example, actively engaged with local communities in Vietnam shipyards through initiatives such as training programs and collaborative clean-up actions. These initiatives exemplify Damen’s commitment to not only addressing industry challenges but also fostering sustainability at a grassroots level.

In essence, the maritime industry stands at the forefront of a transformative era, where sustainability is not merely a trend but a necessity. As shipbuilders, naval architects, and industry stakeholders collectively navigate the complexities of reducing environmental impact, Damen Shipyards’ input serves as a testament to the imperative of collaborative efforts. By fostering innovation, embracing transparency and collaboration to achieve shared sustainability goals, the industry can propel itself toward a future marked by responsible and sustainable maritime operations.

“We want to leave a livable world for the generations to come so in the end we want our industry and all industries to become sustainable”

Enthusiastic about Damen Shipyards or interested in this topic? Contact us at info@platformzero.co and we can tell you more about it!